A Privileged Peek Behind the Scenes: My Visit to the Vaillant Factory

At some point in our lives, we’ve all wondered about the inner workings of the places responsible for crafting the products we rely on daily. When I received an invitation to visit the Vaillant factory, renowned for its exceptional heating solutions, I felt like a kid given the keys to a candy store. It was an opportunity not just to satisfy my curiosity but to delve into the heart of a company committed to warmth, innovation, and sustainability.

Unveiling the Veil on Vaillant

Vaillant is a name synonymous with heating excellence, boasting over a century of expertise in providing warmth and comfort to countless homes and businesses worldwide. As I approached the Vaillant factory gates, I couldn’t help but be struck by the sense of anticipation and excitement in the air.

A Warm Welcome

From the moment I stepped through the doors, I was greeted with warm smiles and an atmosphere of genuine enthusiasm. It was evident that the team at Vaillant took great pride in what they did and were eager to share their passion.

The Dance of Precision Machinery

Walking through the factory, I was struck by the precision and craftsmanship that went into each product. It was a symphony of automation and human expertise working in perfect harmony. The meticulous attention to detail in every step of the manufacturing process was both fascinating and humbling.

Innovation Hub

One of the highlights of my visit was the chance to witness firsthand the innovative spirit that defines Vaillant. Research and development labs buzzed with activity as engineers and scientists tirelessly worked to push the boundaries of heating technology. The commitment to sustainability was evident, with a focus on cutting-edge solutions like heat pumps and hydrogen gas boilers.

A Commitment to Sustainability

What struck me most about Vaillant was their unwavering commitment to sustainability. It wasn’t just a buzzword; it was a guiding principle that permeated every aspect of their operation. From using natural refrigerants with low Global Warming Potential to striving for carbon neutrality in production, Vaillant’s dedication to a greener future was inspiring.

The People Behind the Magic

While the technology and innovation were awe-inspiring, what truly made the visit special were the people I met. From the factory floor to the executive offices, everyone shared a common passion for providing warmth and comfort to customers. Their dedication to excellence was palpable and left a lasting impression on me.

A Privilege and a Pleasure

As I left the Vaillant factory, I couldn’t help but feel a deep sense of privilege. It was an honor to witness the inner workings of a company that has played such a vital role in enhancing the quality of life for countless individuals and families. The experience left me with a renewed appreciation for the craftsmanship, innovation, and dedication that go into creating world-class heating solutions.

In closing, I’d like to extend my heartfelt gratitude to the Vaillant team for extending this incredible opportunity. Visiting the Vaillant factory was not just a privilege; it was a journey into the heart of warmth, innovation, and sustainability. It’s an experience I’ll cherish and one that reaffirmed my belief in the power of dedicated individuals and companies to make a positive impact on our world.

A bit about the factory

Having seen record demand for heat pumps as a result of its successful multi-technology strategy, Vaillant is delighted to announce it is to extend its UK manufacturing facility. Based in Belper, Derbyshire, Vaillant Industrial UK will begin manufacturing heat pumps alongside its UK range of high efficiency boilers from 2022.

Vaillant is one of the only heating appliance manufacturers to produce both high efficiency gas boilers and heat pumps in the UK. Drawing on its vast experience in developing innovative, industry leading heating technologies, Vaillant has invested in significant research and development into heat pumps over the last decade and is unique in its contribution to the UK Government’s strategy for the reduction of carbon emissions from heat and hot water demands.

Having led the innovation of highly efficient gas appliances since 1874, Vaillant believes that no one single technology will address the decarbonisation challenge. A combination of hydrogen gas boilers, heat pumps and hybrid systems along with controls and internet connected solutions will be key to meeting the Government’s targets.

Vaillant Group UK presently manufactures approximately half a million natural gas and liquefied petroleum gas (LPG) appliances at its award-winning and highly efficient Belper facility, serving the needs of the numerous satisfied customers it provides for.

Starting in 2022, the production capacity will be expanded to include the immensely popular aroTHERM plus air-to-water heat pump. Introduced in 2020, the aroTHERM plus stands out as one of the few products on the market utilizing the natural refrigerant R290 with an incredibly low Global Warming Potential of just three. This award-winning heat pump is gaining rapid popularity in the UK market, thanks to its ability to achieve higher flow temperatures of up to 75 degrees.

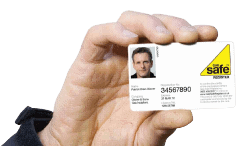

This diversification in the market presents new opportunities and challenges for installers and consumers alike. Vaillant recognizes the urgent need for increased support and training for installers in the industry to equip them with the skills required to accommodate heat pumps if the Government’s target of selling 600,000 heat pumps per year by 2028 is to be met.

To address this need for training and upskilling in heat pump technology, Vaillant offers vocational courses designed to support the transition to new heating technologies. They also provide industry-leading product training and Continuing Professional Development (CPD) with a blended learning approach, allowing individuals to gain knowledge about the decarbonization of heat online or in one of their six Centers of Excellence and other partner training locations across the UK.